Global - manufacturer-independent - fieldbus-independent: The requirements and expectations of IO-Link technology are high and in future they will extend to the standardisation of the smallest and most customised applications.

The effort that manufacturers are making to turn the IO-Link standard into a key technology for flexible, safe and smart manufacturing concepts is correspondingly high. The aim is to establish different IO-Link profiles that bring benefits for end customers, system integrators and device manufacturers alike. The result for all stakeholders is a range of different harmonisation levels of device description files for the control and diagnostics of field sensors. These can be divided into three classes.

IO-Link 1.0

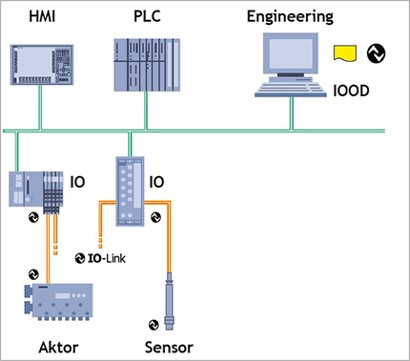

The focus of IO-Link 1.0, the first IO-Link version, is on the ‘last mile’ in the field, more precisely on the signalling and communication connection of sensors and actuators with the higher-level control level. IOL1.0 has successfully brought the intelligence of the sensors down to field level. This enabled data to be recorded, transported and processed with maximum precision directly at the source. The foundation was laid for more efficient and reliable automation.

IO-Link Safety

In addition to the previous developments, IO-Link Safety brings an innovative extension for safety applications in automation technology. Like IO-Link Wireless, IO-Link Safety also arrived in 2022 and now opens up the IO-Link world to safety-relevant components. IO-Link Safety opens up new possibilities for the use of IO-Link in safety-critical environments without compromising on performance or flexibility.

IO-Link Wireless

It was only a matter of time before the IO-Link community took up the topic of wireless data and signal transmission. Since 2022, IO-Link Wireless has provided manufacturers and users with a wireless communication system in automation technology that facilitates planning and, in particular, implementation and operation in industrial automation. This extension enables flexible integration of sensors and actuators without the restrictions of cabling. This not only makes it much easier to adapt automation solutions to changing requirements and environments, it also saves time during installation and maintenance.

Smart Device Profile (SDP)

The continuous further development of IO-Link also had an impact on smart sensor profiles (SSPs). SSP 1.2 was published on 1 January 2024. Compared to its predecessor, SSP 1.2 brings significant functional enhancements, including new elements such as a new switching scheme, a new subprofile, Uncertainty Indication and the Teach Window. expand the possibilities for mapping functions. SSP 1.2 clearly demonstrates how versatile and customisable IO-Link is in industrial automation.