“From computer pioneer to smart factory” – IO-Link Forum at the Heinz Nixdorf MuseumsForum

The IO-Link Forum 2025 in Paderborn, Germany showed impressively how much the spirit of Heinz Nixdorf, one of the most important pioneers of digital information processing in Germany, is still reflected in industrial innovations today. In the museum forum named after him, more than 100 participants discussed the future of networked sensor technology – and how IO-Link makes production processes more intelligent, transparent, and flexible.

Practical and user-oriented

The one-day event offered a compact mix of basic knowledge, current developments, and an accompanying micro-fair where manufacturers presented their IO-Link solutions. The aim of the forum was to introduce end users to the topic of IO-Link in a practical way and highlight the concrete benefits. A particular highlight was the user presentation by HARTING, which provided insights into its digitized production. The company already uses around 500 IO-Link sensors in various areas and utilizes a continuous data chain – from the sensor to the IO-Link master to evaluation via MQTT and Grafana.

Three examples demonstrated the practical benefits:

- Cooling water monitoring: Automated quality control replacing manual sampling

- Cooling lubricant management: Continuous measurement with automatic media correction

- Compressed air leak detection: Early identification of losses increases energy efficiency

Core technologies clearly explained

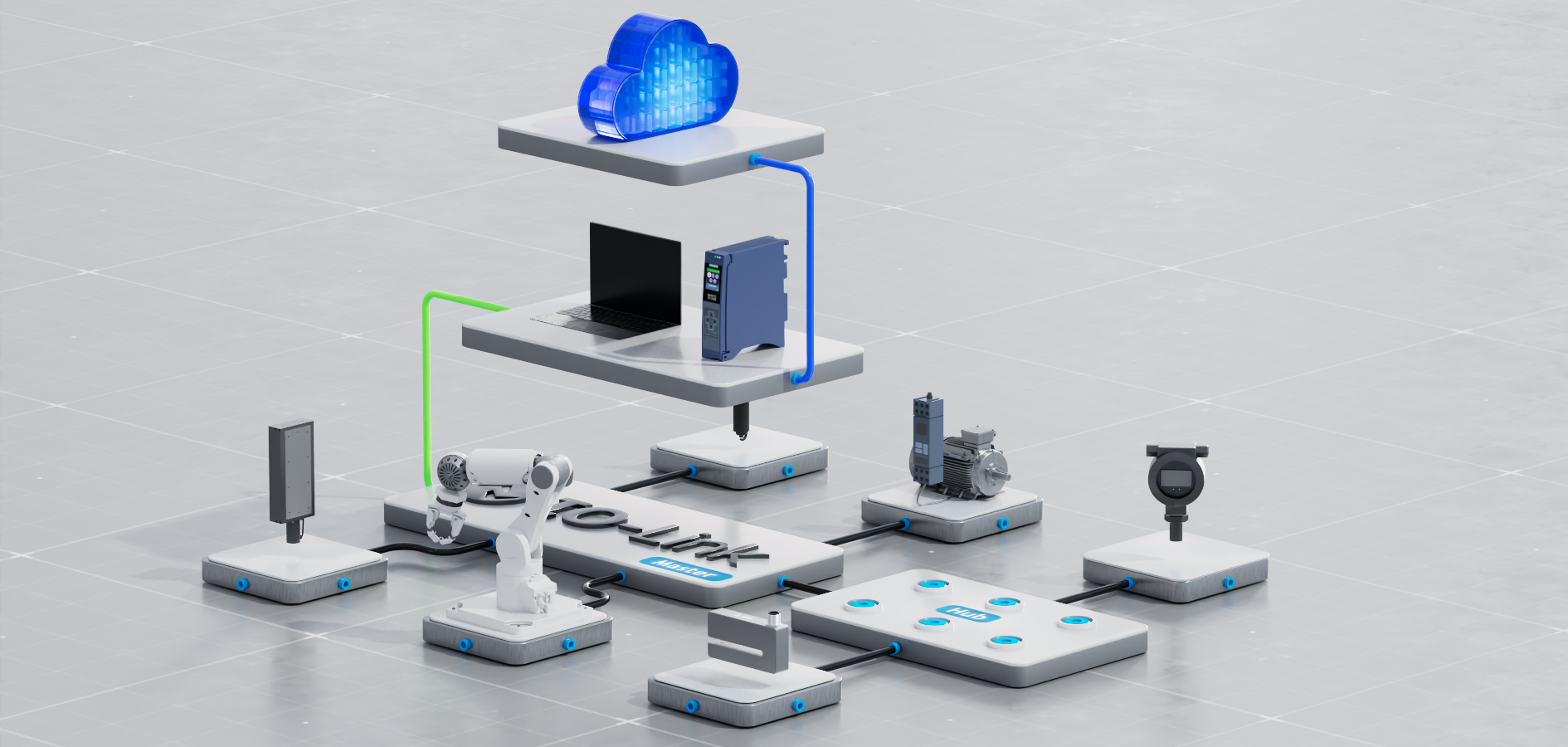

Further presentations introduced the basic principles of IO-Link, current applications, and the new IO-Link profiles, which will significantly simplify cross-manufacturer sensor integration in the future. Topics such as IO-Link Wireless, simplified device integration, and OT/IT networking were also presented clearly and concisely.

Conclusion

The IO-Link Forum demonstrated how practical and visionary the technology has become. Presenting these forward-looking technologies at the Heinz Nixdorf MuseumsForum provided a fitting backdrop: where the foundations of digitalization were once celebrated, the knowledge for tomorrow's smart production is now being created.